Do You Know the Four Common Defects in 304 Stainless Steel Sheet?

Do You Know the Four Common Defects in 304 Stainless Steel Sheet?

Pitting corrosion in 304 Stainless Steel Sheet, also known as pitting, is a form of localized corrosion that occurs in specific corrosive environments. It typically happens in solutions containing halide anions, with chlorides and bromides being the most aggressive, making them common corrosive media for stainless steel. Pitting corrosion usually initiates on the passive film present on the surface of the 304 Stainless Steel Sheet. The corrosion resistance of 304 Stainless Steel Sheet primarily depends on this protective passive film. Although the area affected by pitting is small, once initiated, the corrosion rate can be extremely high, potentially leading to perforation of the equipment in severe cases. Furthermore, pitting often presents a potential risk for initiating intergranular corrosion or stress corrosion cracking.

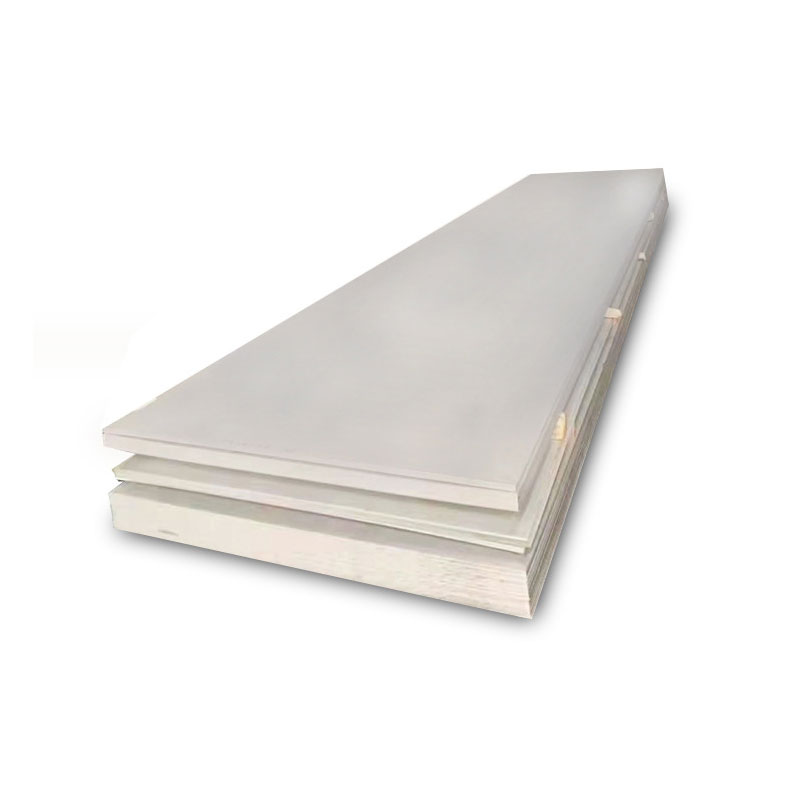

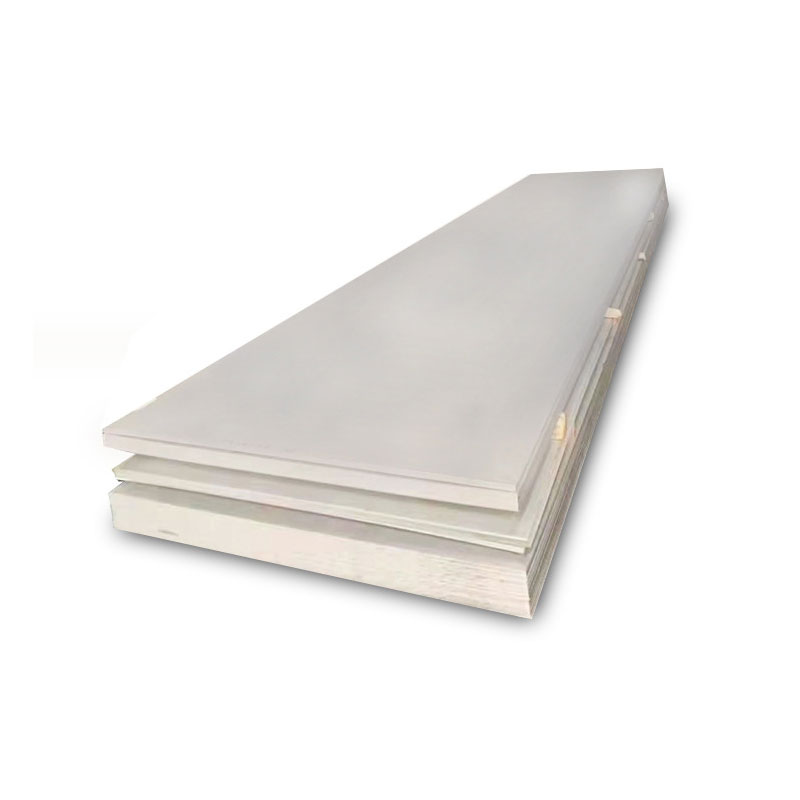

304 Stainless Steel Sheet

The first common defect is weld defects. This is a relatively serious issue, often addressed by manual mechanical grinding. However, this method can easily leave grinding marks on the surface of the sheet, resulting in an uneven appearance and detracting from its aesthetic quality.

The second defect is surface inconsistency. For example, if only the welded area undergoes pickling and passivation, it can lead to an inconsistent appearance across the 304 Stainless Steel Sheet, negatively affecting the final product's visual appeal.

The third defect is that scratches on the surface of the 304 Stainless Steel Sheet are difficult to remove. In severe cases, even overall pickling and passivation cannot eliminate various scratches formed during processing. This can lead to corrosion and rusting when the sheet is exposed to corrosive environments.

The fourth defect involves uneven grinding, polishing, and passivation results. Manual grinding and polishing followed by acid passivation often leads to inconsistent treatment, especially for large workpieces. It is challenging to achieve a uniform and consistent surface finish, making it difficult to obtain an ideally uniform surface. Additionally, the processing time and cost of auxiliary materials for these methods are relatively high.

- A Brief Analysis of the Material Characteristics of Stainless Steel

- Common Degreasing Methods for 310S Stainless Steel Tubes

- Why Do Pores Appear on the Surface of 310S Stainless Steel Sheet?

- What are the measurement methods for straightness of 316L stainless steel?

- Analysis of Causes for Internal Folding in 310S Stainless Steel

- What Are the Application Ranges of 304 Stainless Steel?