Introduction to the Characteristics of 304 Stainless Steel Tube

Introduction to the Characteristics of 304 Stainless Steel Tube

Stainless steel seamless tubes are steel pipes resistant to weak corrosive media such as air, steam, and water, as well as chemically erosive media like acids, alkalis, and salts. They are also known as acid-resistant stainless steel pipes.

The corrosion resistance of stainless steel seamless tubes depends on the alloying elements contained in the steel. Chromium is the fundamental element that imparts corrosion resistance to stainless steel. When the chromium content in the steel reaches approximately 12%, chromium reacts with oxygen in the corrosive medium to form a very thin oxide film (passivation film) on the steel surface, which prevents further corrosion of the steel matrix. In addition to chromium, commonly used alloying elements in 304 Stainless Steel Tube include nickel, molybdenum, titanium, niobium, copper, and nitrogen, to meet the requirements of various applications for the microstructure and properties of stainless steel.

The 304 Stainless Steel Tube is a long, hollow, circular steel product widely used in industrial conveying pipelines for petroleum, chemical, medical, food, light industry, mechanical instrumentation, and other sectors, as well as in mechanical structural components. Furthermore, with the same bending and torsional strength, it is relatively lightweight, making it widely applicable in the manufacturing of mechanical parts and engineering structures. It is also commonly used in the production of various conventional weapons, gun barrels, and artillery shells.

Characteristics:

The greater the wall thickness of the 304 Stainless Steel Tube, the more economical and practical it is. Thinner wall thickness significantly increases processing costs.

The manufacturing process of the 304 Stainless Steel Tube determines its limitations. Generally, seamless steel tubes have low precision: uneven wall thickness, low surface brightness on both inner and outer surfaces, high cutting costs, and pitting and black spots on the inner and outer surfaces that are difficult to remove.

Testing and shaping of the 304 Stainless Steel Tube must be performed offline. Therefore, it demonstrates superior performance in applications involving high pressure, high strength, and mechanical structural materials.

- Degreasing Methods for Common 310S Stainless Steel Tubes

- Selection of Thickness for 316L Stainless-Steel Gutter

- What Are the Differences Between 201 and 304 Stainless Steel Profiles?

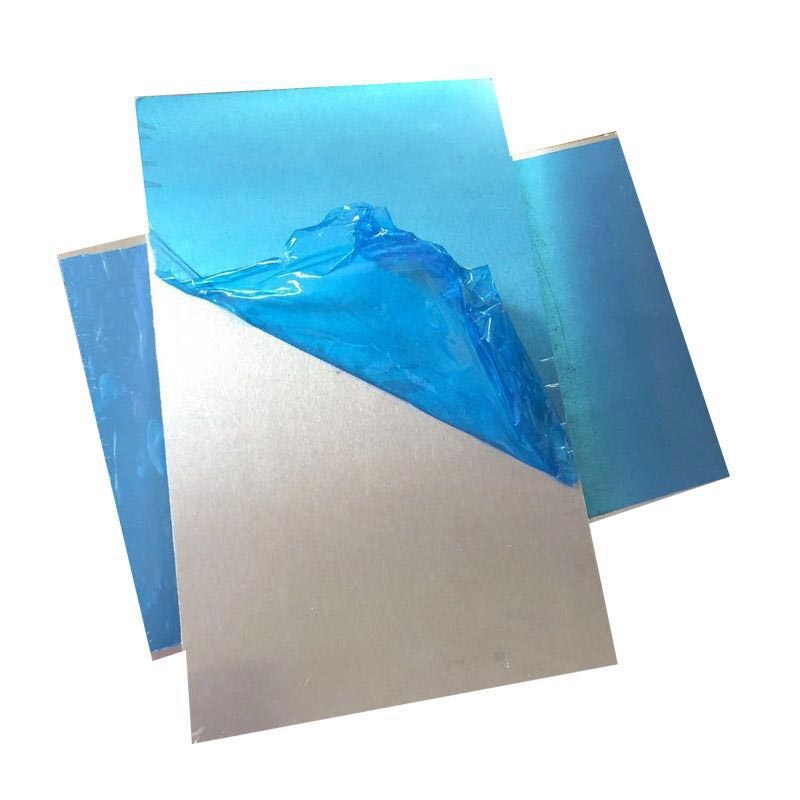

- What Challenges Arise When Cutting 304 Stainless Steel Sheet?

- How to Solve the Problem of Rust Spots on Stainless Steel Coils

- How to Increase the Service Life of Stainless Steel Tubes?