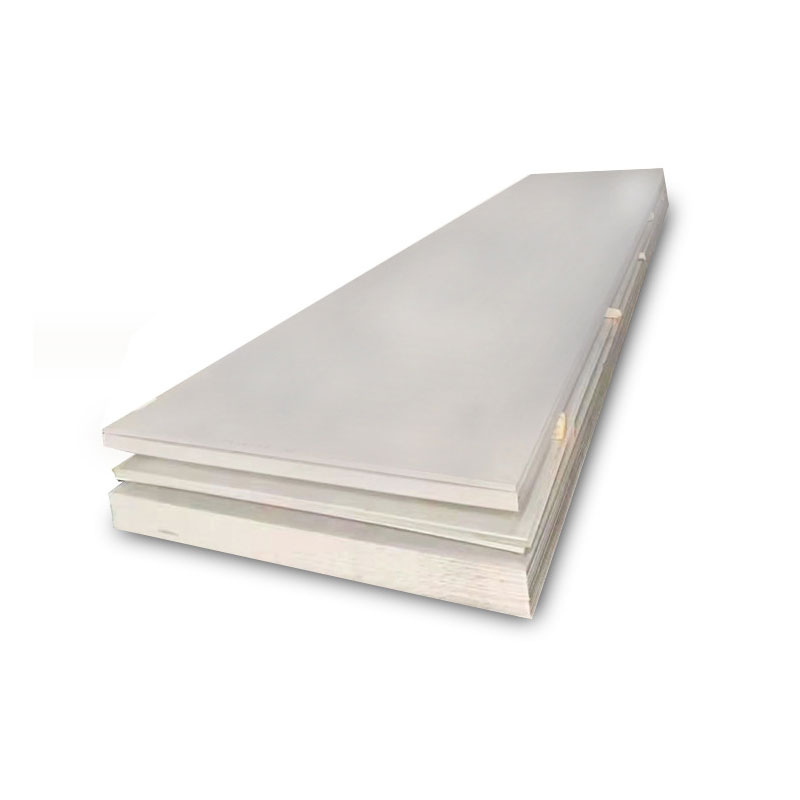

What Should Be Noted When Forming 316L Stainless Steel Sheet?

What Should Be Noted When Forming 316L Stainless Steel Sheet?

When the formability of 316L Stainless Steel Sheet becomes relatively poor, its high strength can largely lead to a decrease in plasticity. The increase in yield strength tends to cause surface distortion and springback effects, thereby enhancing the shape instability of the 316L Stainless Steel Sheet.

As mentioned above, improving the strength of 316L Stainless Steel Sheet often results in reduced plasticity. This, in turn, directly lowers the limits for bulging fracture and stretch flanging fracture. With the enhancement of the sheet's strength, the occurrence of cracks becomes more likely.

Furthermore, it is important to note that when significant forming force is required and the mold temperature rises during continuous processing, sticking phenomena may occur to a large extent. This can, to a certain degree, induce the formation of cracks.

Additionally, an increase in the yield point of 316L Stainless Steel Sheet can easily lead to wrinkling. Wrinkling not only causes mold sticking and crack generation but is also difficult to eliminate in the later stages of forming. Consequently, it often results in poor shape quality. Since wrinkling cannot be removed in the later forming stages, stamped parts cannot be fully formed at the bottom dead center.

Finally, issues with dimensional accuracy of the 316L Stainless Steel Sheet may arise. As material strength increases, residual stress also rises, making it easier for phenomena such as shape inaccuracies and dimensional precision errors (springback) to occur due to elastic recovery after forming.

- Degreasing Methods for Common 310S Stainless Steel Tubes

- Selection of Thickness for 316L Stainless-Steel Gutter

- What Are the Differences Between 201 and 304 Stainless Steel Profiles?

- What Challenges Arise When Cutting 304 Stainless Steel Sheet?

- How to Solve the Problem of Rust Spots on Stainless Steel Coils

- How to Increase the Service Life of Stainless Steel Tubes?