What are the Requirements for Anti-Corrosion Construction of 316L Stainless Steel Sheet?

What are the Requirements for Anti-Corrosion Construction of 316L Stainless Steel Sheet?

Processed prefabricated components and finished products must pass inspection before surface treatment can be carried out.

Surface imperfections such as burrs, welding spatter, weld scars, splatter, dust, and scale on the 316L Stainless Steel Sheet should be cleaned prior to rust removal. Loose oxide layers and thick rust deposits must also be removed.

If the surface of the 316L Stainless Steel Sheet is contaminated with oil or grease, it must be thoroughly cleaned before rust removal. For localized contamination, spot cleaning methods may be used; for large-area or full-surface contamination, organic solvents or hot alkaline solutions should be employed.

If acid, alkali, or salt residues are present on the surface of the 316L Stainless Steel Sheet, they can be removed using hot water or steam cleaning. However, wastewater must be properly treated to avoid environmental pollution.

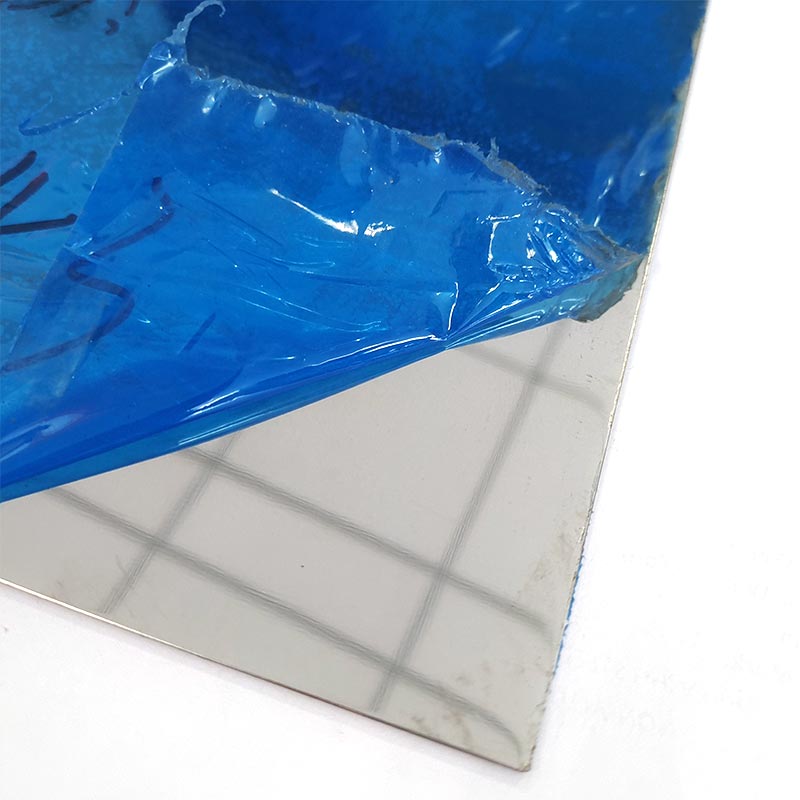

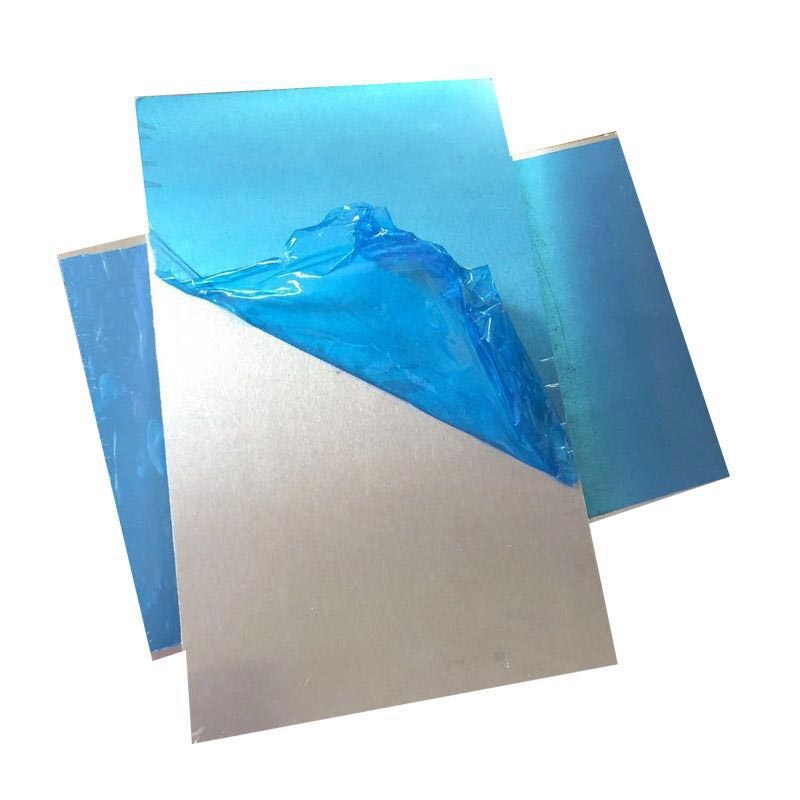

Some newly cold-rolled 316L Stainless Steel Sheets are coated with protective paint to prevent rust during short-term storage and transportation. The treatment of such coated sheets depends on the specific situation. If the protective paint is a two-component coating cured with a hardening agent and the coating remains largely intact, methods such as sanding, brushing with stainless steel velvet, or light blasting can be used to roughen the surface. After removing dust, subsequent processes can proceed.

For 316L Stainless Steel Sheets coated with workshop primer or general primer for protection, the treatment method generally depends on the condition of the coating and the requirements of the next coating layer. Any coating that cannot be overcoated or may affect the adhesion of the next layer must be completely removed.

When using fire-resistant coatings for 316L Stainless Steel Sheet structures, the following points should be noted:

Do not use decorative fire-resistant coatings for 316L Stainless Steel Sheet structures. Decorative fire-resistant coatings are designed to protect combustible materials like wood structures. Their thin coatings cannot achieve the intended fire resistance rating for 316L Stainless Steel Sheet structures.

Thin-film intumescent fire-resistant coatings for 316L Stainless Steel Sheet structures should not be used for protection requiring more than 1 hour of fire resistance. For fire resistance ratings exceeding 1 hour, thick-film fire-resistant thermal insulation coatings must be used.

Indoor fire-resistant coatings for 316L Stainless Steel Sheet structures should not be directly applied to outdoor structures without modification and effective waterproofing measures.

Thick-film fire-resistant coatings are primarily composed of inorganic materials, offering stable coatings and slow aging. As long as the coating does not peel off, fire safety performance is ensured. For durability and fire safety, thick-film fire-resistant coatings are recommended.

The structural system of 316L Stainless Steel Sheet is a common form of steel structure, widely used in large-span commercial buildings, industrial plants, and structures with specific requirements for space, form, and function. Today, the application of 316L Stainless Steel Sheet in structural environments is gaining increasing attention. The structural system of 316L Stainless Steel Sheet can generally be categorized into single-span single-layer, multi-span single-layer, and multi-span multi-layer configurations to meet the needs of different architectural forms and functions.

- Degreasing Methods for Common 310S Stainless Steel Tubes

- Selection of Thickness for 316L Stainless-Steel Gutter

- What Are the Differences Between 201 and 304 Stainless Steel Profiles?

- What Challenges Arise When Cutting 304 Stainless Steel Sheet?

- How to Solve the Problem of Rust Spots on Stainless Steel Coils

- How to Increase the Service Life of Stainless Steel Tubes?