Stainless Steel Sheet Manufacturer: Common Size Specifications for Stainless Steel Sheets

Stainless Steel Sheet Manufacturer: Common Size Specifications for Stainless Steel Sheets

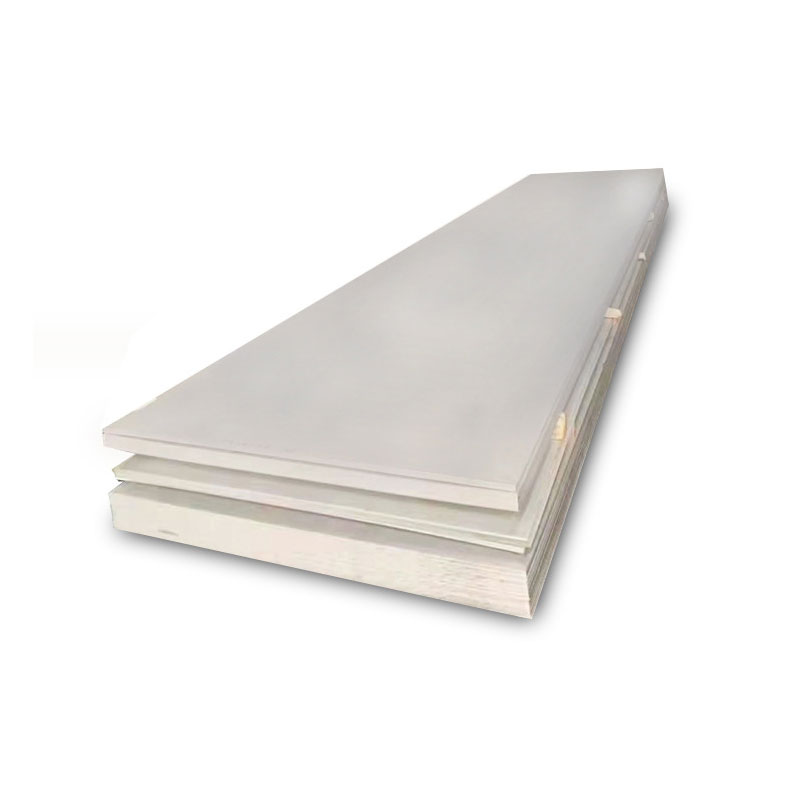

The use of stainless-steel-sheet has become a new type of material alongside the development of the modern construction industry and can be seen everywhere in daily life. When we typically use them for production, what are the available size models we can choose from?

Common Size Specifications for Stainless Steel Sheets

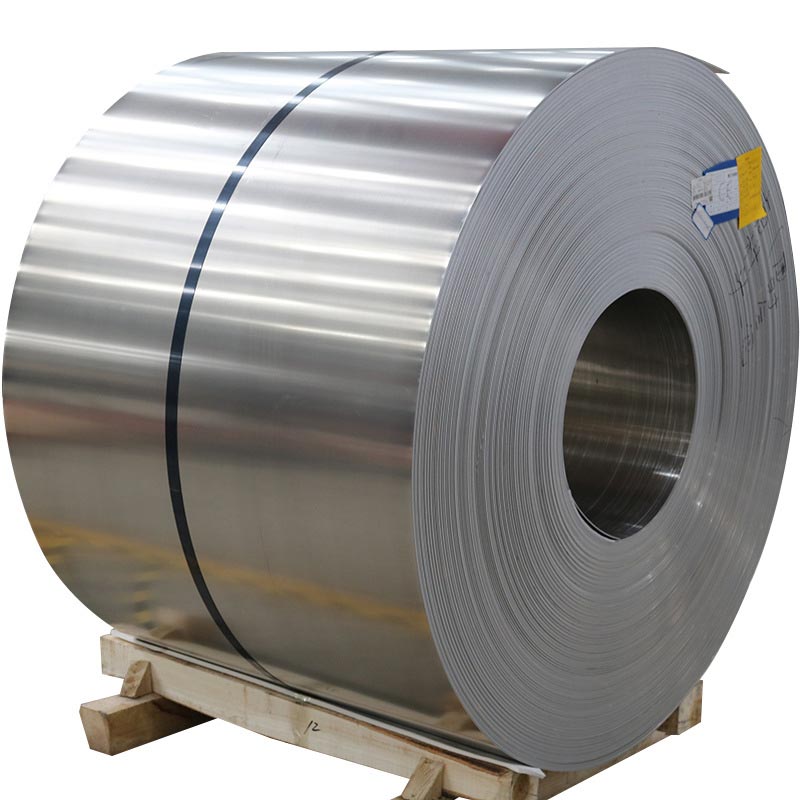

Types and Materials of Stainless Steel Sheets: 304, 316L, 321, 201, (301 coil). Domestic stainless-steel-sheet: 430, 409, 201.

304 Stainless Steel Sheet Thickness: 0.12mm – 65mm. 316L Stainless Steel Sheet Thickness: 0.5mm – 16mm.

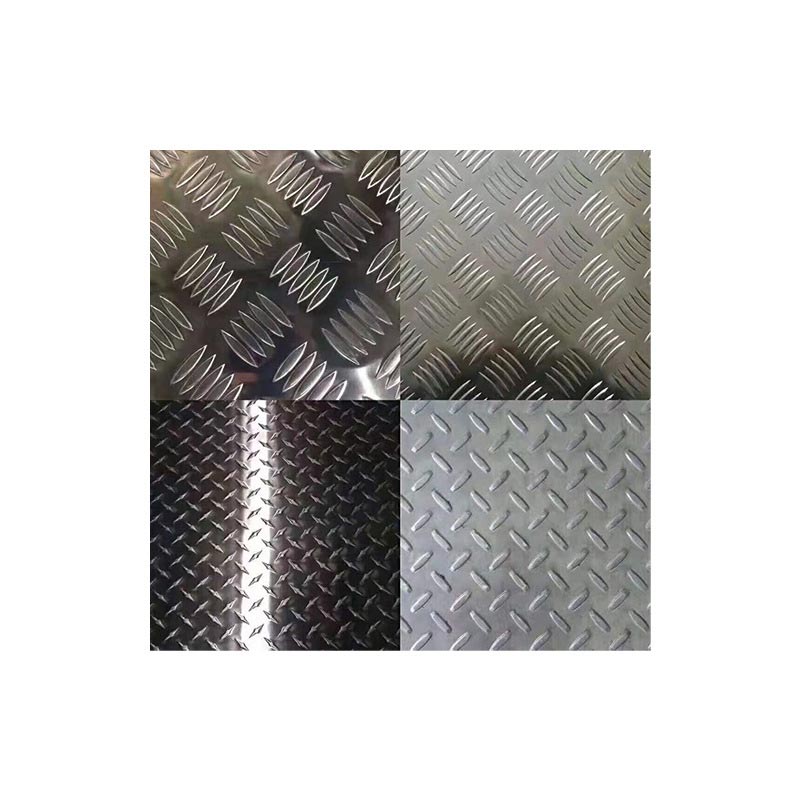

Sheet Surface Treatments: 8K mirror, 2B bright surface, satin (brushed, sanded), titanium gold, bead blasted, oil-brushed, BA sheet.

Sheet Widths: 1000mm * 2000mm, 1219mm * 2438mm, 1219mm * 3048mm, 1219mm * 3500mm, 1219mm * 4000mm, 1500mm * 3000mm, 1500mm * 6000mm.

When we typically use stainless-steel-sheet, it is essential to understand the various models and sizes clearly. This allows us to proceed with production and usage based on specific requirements.

Tips for the Heat Treatment Process of Stainless Steel Sheets

Heat treatment of stainless-steel-sheet is used to alter its physical and mechanical properties without changing its shape. It is an indispensable process in the manufacturing of stainless-steel-sheet, adding ideal characteristics and enabling further processing. Different heat treatment processes for stainless-steel-sheet involve heating and cooling. For example, steel undergoes heat treatment for various commercial applications.

The common purposes of heat treatment are to enhance strength, increase hardness, improve toughness, improve machinability, enhance formability, increase ductility, and improve elasticity, among others. The effect of the cooling stage varies depending on the stainless-steel-sheet and the process. Steel becomes hard when cooled rapidly, whereas the rapid cooling stage in solution annealing serves to soften it.

Although there are many types of heat treatment for stainless-steel-sheet, the two most important heat treatment methods are annealing and tempering. Annealing involves heating the steel to a specified temperature and then cooling it at a very slow and controlled rate. Annealing is used to soften stainless-steel-sheet for cold working, improve machinability, and enhance electrical conductivity. Annealing can also restore ductility. During cold working, a stainless-steel-sheet can harden to the point of causing cracking. By pre-annealing the stainless-steel-sheet, cold working can be performed without the risk of cracking. Annealing releases mechanical stresses generated during processing or grinding.

- A Brief Analysis of the Material Characteristics of Stainless Steel

- Common Degreasing Methods for 310S Stainless Steel Tubes

- Why Do Pores Appear on the Surface of 310S Stainless Steel Sheet?

- What are the measurement methods for straightness of 316L stainless steel?

- Analysis of Causes for Internal Folding in 310S Stainless Steel

- What Are the Application Ranges of 304 Stainless Steel?