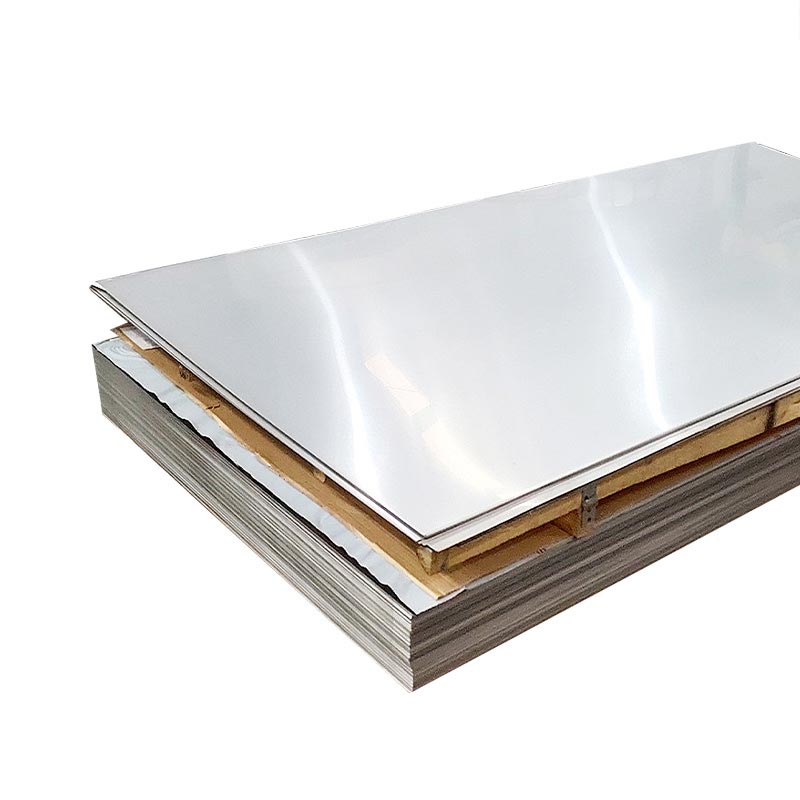

How to Deal with Decarburization of 304 Stainless Steel Sheet?

How to Deal with Decarburization of 304 Stainless Steel Sheet?

The requirements for decarburization treatment of 304 stainless steel sheets involve decarburizing (and deoxidizing) molten steel under vacuum, which is based on the influence of pressure on chemical reactions. A decrease in the partial pressure of carbon monoxide promotes the decarburization process. Since, under atmospheric pressure and low carbon conditions, [Cr] oxidizes before [C], producing low-carbon 304 stainless steel sheets in electric arc furnaces or converters is not easy. This leads to excessive loss of chromium yield and necessitates the use of high-cost, low-carbon ferrochromium alloys.

The VOD (Vacuum Oxygen Decarburization) refining process is used for 304 stainless steel sheets. This equipment features high vacuum levels, strong decarburization capability, and high bottom-blowing capacity, fully meeting the requirements for decarburization treatment of 304 stainless steel sheets. During the VOD vacuum treatment process, the decarburization rate is influenced by various factors and has a clear relationship with the initial carbon content before VOD treatment. The decarburization rate increases with higher initial carbon content. Results show that under different initial carbon contents, the decarburization rate follows a trend across three distinct stages. Among these, the decarburization rate is lower in the first stage, while the second and third stages have similar rates. However, when the initial carbon content is low, the decarburization rate in the third stage remains relatively high.

To enable spot welding between ultra-thin steel sheets or spot welding ultra-thin sheets to thick forgings, and to meet the needs of spot welding complex-shaped workpieces with non-conductive basalt fiber backing (requiring single-sided spot welding), it is essential to select suitable processes, equipment, and welding auxiliary devices. Simultaneously, based on the characteristics of spot welding ultra-thin steel sheets, process tests should be conducted to determine the optimal process parameters.

The process lubrication system for the 304 stainless steel sheet cold rolling mill is a crucial part of the unit, directly impacting its production capacity and product quality. To improve performance, the following aspects can be considered for proper product selection:

Confirm whether the mechanical properties of the product meet usage requirements (such as the tensile strength of bolts, the safe load of nuts, etc.) before use.

Select bolts of appropriate length so that 1-2 threads protrude from the nut after tightening.

Use bolts and nuts of different grades along with washers.

Ensure threads are clean before use.

Apply lubricant (such as 40# engine oil, grease, graphite, etc.) to lubricate internal and external threads before use.

304 stainless steel sheets are primarily used in industrial conveying pipelines and mechanical structural components for petroleum, chemical, medical, food, light industry, machinery, instrumentation, and other sectors. As they offer lighter weight while maintaining equivalent bending and torsional strength, they are also widely used in manufacturing mechanical parts and engineering structures. They are also used in producing various conventional weapons, gun barrels, shells, etc.

For most applications, the primary requirement is long-term preservation of the building's original appearance. When determining the type of stainless steel to select, the main considerations are the desired aesthetic standards, the corrosiveness of the local atmosphere, and the intended cleaning regime. However, an increasing number of other applications seek only structural integrity or impermeability, such as industrial building roofs and side walls.

The atmospheric corrosion resistance of 304 stainless steel sheet is significantly improved. While corrosion resistance still increases with higher chromium content, the improvement is not dramatic. The reason is that when steel is alloyed with chromium, the type of surface oxide changes to resemble that formed on pure chromium metal. This tightly adherent, chromium-rich oxide protects the surface, preventing further oxidation. This oxide layer is very thin, and the natural luster of the steel surface can be seen through it, giving stainless steel its unique appearance. Furthermore, if the surface layer is damaged, the exposed steel surface reacts with the atmosphere to self-repair, re-forming this passive film and continuing its protective role.

304 stainless steel sheet is a long, hollow steel product widely used as piping for transporting fluids such as oil, natural gas, water, and steam. Furthermore, due to its light weight while maintaining equal bending and torsional strength, it is also extensively used in the manufacture of mechanical parts and engineering structures.

- Degreasing Methods for Common 310S Stainless Steel Tubes

- Selection of Thickness for 316L Stainless-Steel Gutter

- What Are the Differences Between 201 and 304 Stainless Steel Profiles?

- What Challenges Arise When Cutting 304 Stainless Steel Sheet?

- How to Solve the Problem of Rust Spots on Stainless Steel Coils

- How to Increase the Service Life of Stainless Steel Tubes?