What Are the Processing Techniques for Carbon Steel Coil?

What Are the Processing Techniques for Carbon Steel Coil?

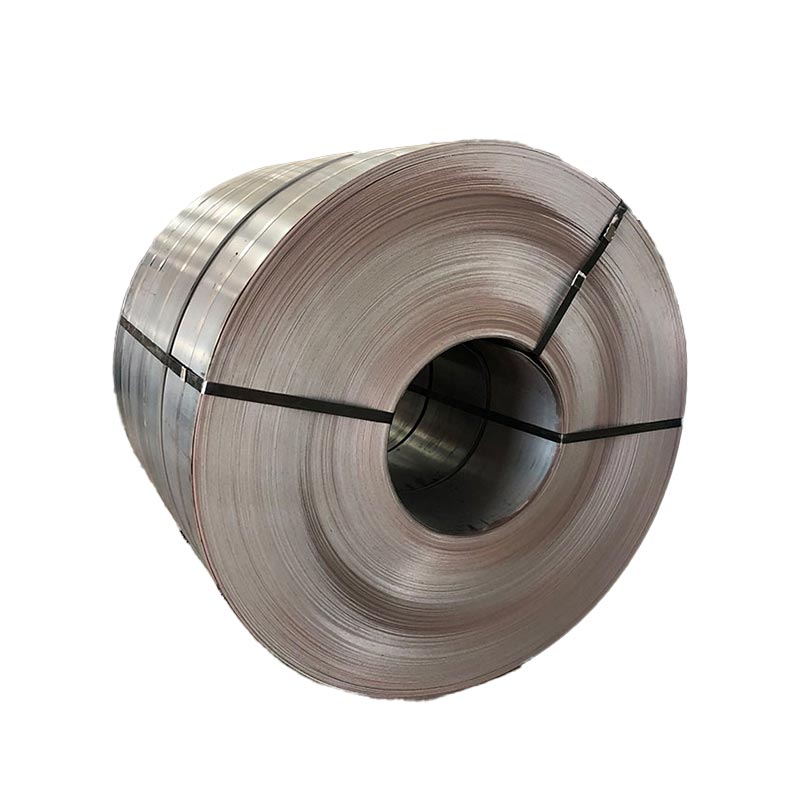

Carbon Steel Coil is a fundamental material widely used in manufacturing due to its excellent plasticity and strength. The processing techniques for Carbon Steel Coil are diverse, including cutting, stamping, bending, welding, and surface treatment. These methods enable Carbon Steel Coil to meet various industrial requirements in automotive manufacturing, construction, and appliance production.

In cutting processes, Carbon Steel Coil can be slit or sectioned using laser cutting, plasma cutting, or mechanical shearing. The high-precision cutting of Carbon Steel Coil ensures efficiency in subsequent processing while minimizing material waste. Stamping, another common technique, utilizes molds to shape Carbon Steel Coil into components like automotive parts and metal enclosures.

Bending and roll forming are frequently applied to Carbon Steel Coil for producing pipes, brackets, and curved structures. Welding joins multiple sections of Carbon Steel Coil to create larger assemblies, widely used in structural steel buildings and pressure vessels. Additionally, surface treatments such as galvanizing, painting, or anodizing enhance the corrosion resistance of Carbon Steel Coil.

In summary, Carbon Steel Coil offers versatile processing techniques to meet diverse industrial needs. With its exceptional workability, Carbon Steel Coil remains an indispensable material in modern manufacturing.

- Why Does Tinplate Steel Win Real-World Packaging Projects Today?

- Surface Quality Inspection Methods and Precautions for 304 Stainless Steel Sheet

- What is the Manufacturing Process of Stainless Steel Tube?

- Welding Quality Measures for 304 Stainless Steel Seamless Tubes

- How to Choose the Stainless Steel Tube for Your Industrial Needs?

- Bright Annealing Conditions for 304 Stainless Steel Tube