What Makes Stainless Steel the Ideal Material for Modern Industrial and Commercial Applications?

In the realm of materials science, few substances have revolutionized industries as profoundly as stainless steel. From skyscraper facades to kitchen appliances, medical equipment to marine structures, stainless steel has become a cornerstone of modern manufacturing and construction. Its unique combination of durability, corrosion resistance, and versatility has made it indispensable across sectors, adapting to evolving demands for sustainability, safety, and performance. As businesses and consumers increasingly prioritize long-lasting, low-maintenance materials, understanding what sets stainless steel apart as a material of choice is essential. This guide explores the exceptional properties of stainless steel, its diverse applications, detailed specifications of our premium grades, and answers to common questions to highlight its enduring value in industrial and commercial settings.

Trending News Headlines: Top Searches on Stainless Steel

- "Stainless Steel Recycling Rates Hit Record High Amid Green Initiatives"

- "Why Food-Grade Stainless Steel Is a Must for Commercial Kitchens"

These headlines underscore key industry focuses: advancing material performance, embracing sustainability through recycling, and ensuring safety in critical applications like food processing. For businesses, staying informed about these trends is crucial to selecting the right stainless steel grade for their needs while aligning with environmental and regulatory standards.

Why Stainless Steel Stands Out as a Superior Material

Exceptional Corrosion Resistance

Unlike regular steel, which rusts when exposed to moisture and oxygen, stainless steel contains chromium (at least 10.5%), which forms a thin, invisible oxide layer on its surface. This layer, known as the passive layer, acts as a protective barrier, preventing further oxidation and corrosion. Even if the surface is scratched, the chromium in the steel reacts with oxygen to repair the layer, ensuring long-term resistance. This property makes stainless steel ideal for environments with high humidity, exposure to chemicals, or saltwater—such as marine structures, chemical processing plants, and outdoor architectural elements. For example, coastal bridges built with stainless steel components require minimal maintenance compared to those using carbon steel, reducing long-term costs and extending service life.

High Strength and Durability

Stainless steel offers an impressive strength-to-weight ratio, making it suitable for load-bearing applications without excessive bulk. Its mechanical properties—including tensile strength, impact resistance, and hardness—can be further enhanced through alloying with elements like nickel, molybdenum, or nitrogen. For instance, austenitic stainless steels (such as 304 and 316) retain their strength at both high and low temperatures, making them ideal for extreme environments like industrial furnaces or cryogenic storage. This durability translates to a longer lifespan for products and structures, reducing the need for frequent replacements and minimizing waste—a key advantage for sustainability.

Hygiene and Safety Compliance

Stainless steel’s non-porous surface prevents the absorption of bacteria, mold, or other contaminants, making it easy to clean and sanitize. This property is critical in industries where hygiene is paramount, such as food processing, pharmaceuticals, and healthcare. Food-grade stainless steels (like 304 and 316) meet strict regulatory standards (e.g., FDA, EU 10/2011) for contact with consumables, ensuring no harmful substances leach into products. In hospitals, stainless steel medical equipment and surfaces can be sterilized with high temperatures or harsh chemicals without degradation, reducing the risk of infections. For businesses, this compliance not only ensures safety but also avoids costly recalls or regulatory penalties.

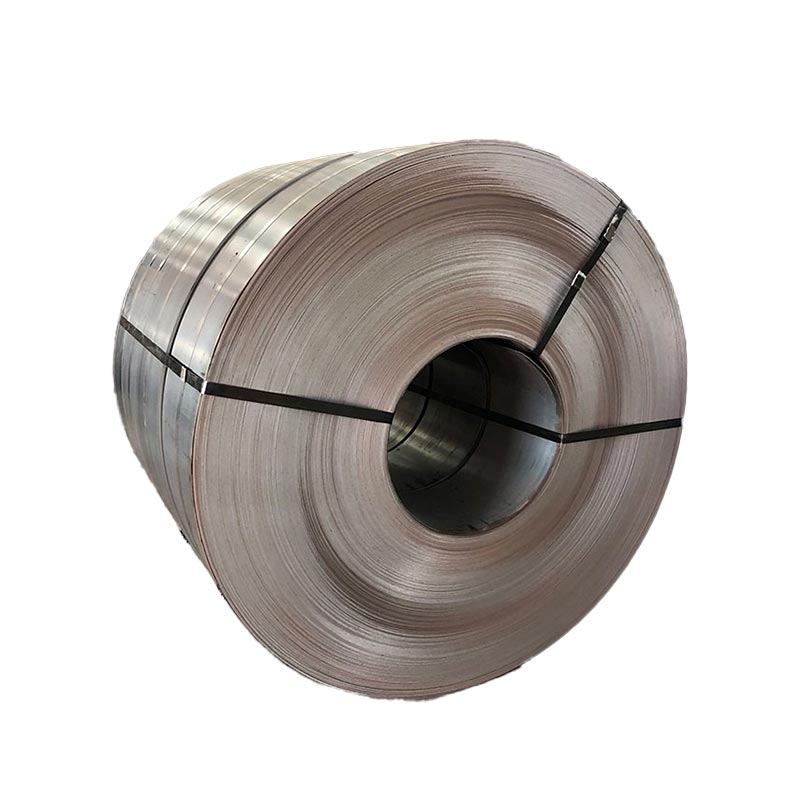

Versatility and Customizability

Stainless steel is available in over 150 grades, each formulated to meet specific needs—from high corrosion resistance to enhanced formability or magnetic properties. This versatility allows businesses to select a grade tailored to their application: for example, 316 stainless steel, with added molybdenum, is preferred for marine environments due to its resistance to saltwater corrosion, while 430 stainless steel, a ferritic grade, is used in decorative applications for its cost-effectiveness and magnetic properties. Additionally, stainless steel can be fabricated into various forms—sheets, tubes, wires, or custom shapes—using processes like welding, bending, or machining, making it adaptable to complex designs.

Sustainability and Recyclability

Stainless steel is 100% recyclable, with a recycling rate of over 90% in many industries—the highest among engineering materials. Unlike plastics or composites, which degrade during recycling, stainless steel retains its properties through multiple recycling cycles, reducing the need for virgin raw materials. This not only conserves natural resources but also lowers carbon emissions: recycling stainless steel uses 75% less energy than producing it from ore. For businesses aiming to reduce their environmental footprint, using recycled stainless steel or investing in products with high recyclability aligns with circular economy goals and appeals to eco-conscious consumers.

Key Factors to Consider When Selecting Stainless Steel Grades

Alloy Composition

The alloying elements in stainless steel determine its properties:

- Chromium: Enhances corrosion resistance (minimum 10.5%).

- Nickel: Improves ductility, toughness, and resistance to high temperatures (common in austenitic grades).

- Molybdenum: Boosts resistance to pitting and crevice corrosion (key in 316 grade).

- Carbon: Increases strength but may reduce corrosion resistance (controlled in low-carbon grades like 304L).

- Nitrogen: Enhances strength without compromising ductility.

Assess the environment where the stainless steel will be used:

- Mild Environments: Indoor applications with low moisture (e.g., 430 grade for appliances).

- Moderate Exposure: Outdoor or humid conditions (e.g., 304 grade for architectural cladding).

- Severe Environments: Saltwater, chemicals, or high humidity (e.g., 316 grade for marine equipment).

Consider the mechanical stresses the material will endure:

- Tensile Strength: Important for load-bearing structures (e.g., 316 has a tensile strength of 515-690 MPa).

- Formability: Critical for bending or shaping (austenitic grades like 304 are highly formable).

- Heat Resistance: Necessary for high-temperature applications (e.g., 310 grade withstands up to 1150°C).

While higher-grade stainless steels (like 316) offer superior properties, they come at a higher cost due to alloying elements like nickel. Balancing performance needs with budget is key—for example, 304 grade provides excellent value for most general applications, while 316 is worth the investment for harsh environments.

Our Premium Stainless Steel Specifications

|

Feature

|

304 Stainless Steel

|

316 Stainless Steel

|

430 Stainless Steel

|

310S Stainless Steel

|

|

Alloy Composition

|

18-20% Cr, 8-10.5% Ni, ≤0.08% C

|

16-18% Cr, 10-14% Ni, 2-3% Mo, ≤0.08% C

|

16-18% Cr, ≤0.12% C, no Ni

|

24-26% Cr, 19-22% Ni, ≤0.08% C

|

|

Corrosion Resistance

|

Excellent in mild to moderate environments; resistant to atmospheric corrosion and food acids

|

Superior to 304; resistant to saltwater, chemicals, and pitting

|

Good in dry environments; susceptible to corrosion in high humidity

|

Exceptional heat and oxidation resistance up to 1150°C

|

|

Tensile Strength

|

515-690 MPa

|

515-690 MPa

|

450-600 MPa

|

520-720 MPa

|

|

Yield Strength

|

≥205 MPa

|

≥205 MPa

|

≥205 MPa

|

≥205 MPa

|

|

Elongation

|

≥40%

|

≥40%

|

≥20%

|

≥40%

|

|

Hardness (Brinell)

|

≤201 HB

|

≤217 HB

|

≤183 HB

|

≤217 HB

|

|

Formability

|

Excellent (easily welded, bent, stamped)

|

Excellent (similar to 304)

|

Good (limited weldability)

|

Good (requires specialized welding)

|

|

Magnetic Properties

|

Non-magnetic

|

Non-magnetic

|

Magnetic

|

Non-magnetic

|

|

Common Applications

|

Food processing equipment, kitchen appliances, architectural cladding, chemical storage

|

Marine components, coastal structures, pharmaceutical equipment, wastewater treatment

|

Automotive trim, decorative panels, mild indoor appliances

|

Furnace parts, heat exchangers, high-temperature industrial ovens

|

|

Compliance

|

FDA, EU 10/2011, ASTM A240

|

FDA, EU 10/2011, ASTM A240

|

ASTM A240

|

ASTM A240, ASME SA-240

|

|

Thickness Range

|

0.3mm - 100mm (sheets); 6mm - 500mm (plates)

|

0.3mm - 100mm (sheets); 6mm - 500mm (plates)

|

0.3mm - 50mm (sheets); 6mm - 200mm (plates)

|

0.5mm - 100mm (sheets); 10mm - 300mm (plates)

|

|

Surface Finish Options

|

2B, No. 1, No. 4, BA, HL (hairline)

|

2B, No. 1, No. 4, BA, HL

|

2B, No. 1, No. 4

|

2B, No. 1, matte

|

Our 304 stainless steel is the industry standard for general applications, offering a perfect balance of corrosion resistance, formability, and cost-effectiveness. The 316 grade is our premium option for harsh environments, ideal for marine, chemical, and pharmaceutical use. For decorative or low-cost indoor applications, 430 stainless steel provides reliable performance with magnetic properties. The 310S grade caters to high-temperature industries, maintaining strength and oxidation resistance in extreme heat. All our stainless steel products undergo rigorous testing to ensure they meet ASTM, ISO, and industry-specific standards, guaranteeing quality and consistency.

FAQ: Common Questions About Stainless Steel

- Why Does Tinplate Steel Win Real-World Packaging Projects Today?

- Surface Quality Inspection Methods and Precautions for 304 Stainless Steel Sheet

- What is the Manufacturing Process of Stainless Steel Tube?

- Welding Quality Measures for 304 Stainless Steel Seamless Tubes

- How to Choose the Stainless Steel Tube for Your Industrial Needs?

- Bright Annealing Conditions for 304 Stainless Steel Tube