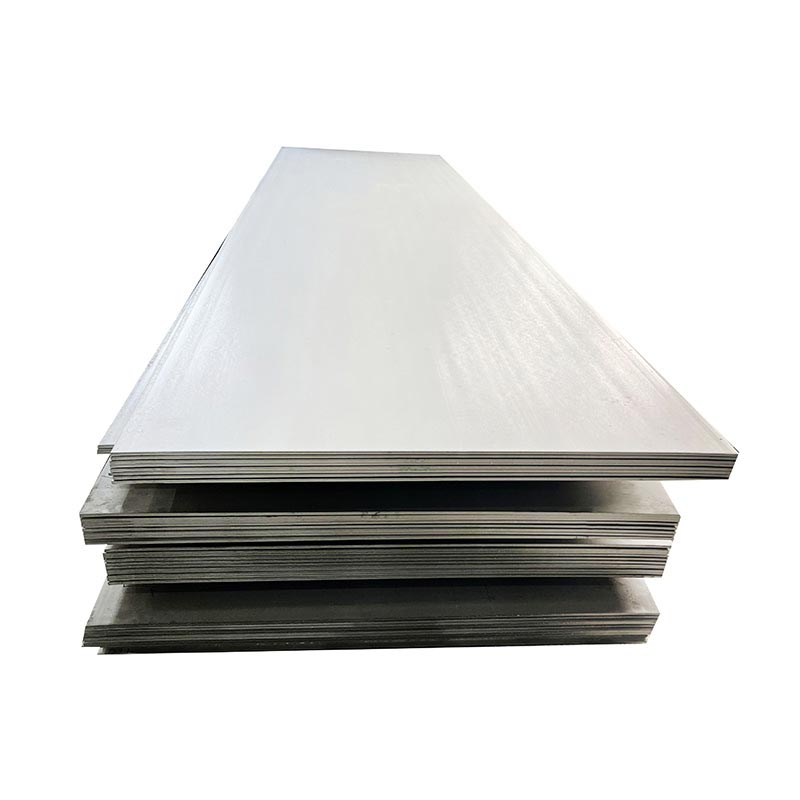

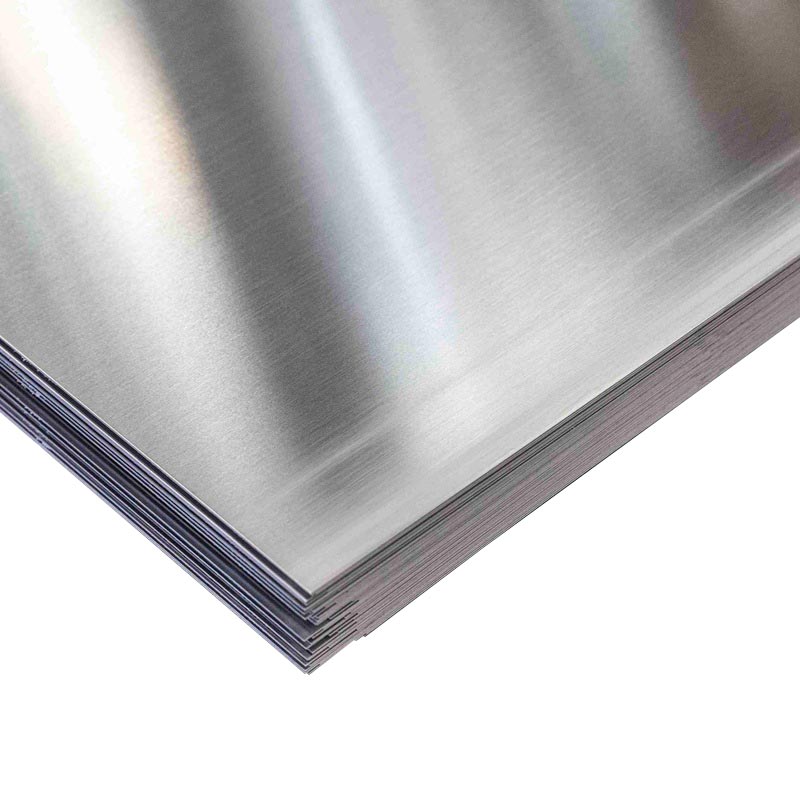

321 NO.1 2B BA Cold Rolled Stainless Steel Strip

Discover the pinnacle of metal excellence with our premium 321 Stainless Steel Strip, designed for superior performance in extreme environments. Our Cold Rolled Stainless Steel products, including the high-grade 2B Finish Stainless and BA Finish Stainless strips, offer exceptional durability and corrosion resistance. These materials are ideal for applications requiring robust Stainless Steel Strip solutions, such as aerospace, chemical processing, and automotive industries. With precise engineering and strict quality control, our strips ensure reliable performance and long-term value for your projects.

321 NO.1 2B BA Cold Rolled Stainless Steel Strip represents a top-tier product in the stainless steel market, characterized by its excellent mechanical properties and aesthetic appeal. This strip is manufactured through a cold rolling process that enhances its strength and surface quality, making it suitable for demanding applications where both formability and resistance to high temperatures are crucial. The NO.1 finish provides a rough, scaled surface ideal for industrial uses, while the 2B finish offers a smooth, slightly reflective surface common in general applications, and the BA (Bright Annealed) finish delivers a mirror-like, highly reflective appearance perfect for decorative and精密 components. Key parameters include a thickness range from 0.1mm to 3.0mm, width options from 10mm to 1000mm, and standard lengths up to 2000mm, though custom dimensions are available. The material composition typically features chromium (17-19%), nickel (9-12%), and titanium (5xC min) for stabilization against carbide precipitation, ensuring enhanced weldability and intergranular corrosion resistance. Mechanical properties boast a tensile strength of 515 MPa minimum, yield strength of 205 MPa minimum, and elongation of 40% minimum, providing excellent ductility and toughness. Surface finishes adhere to international standards like ASTM A240, with the NO.1 finish having a dull, hot-rolled appearance, the 2B finish being cold-rolled, annealed, and pickled for a smooth matte look, and the BA finish achieved through bright annealing for a glossy surface. Applications span across heat exchangers, furnace parts, and exhaust systems, where its ability to withstand temperatures up to 900°C makes it indispensable. Available in various grades and certifications, including ASME and ISO, this strip ensures compliance with global quality benchmarks, offering reliability for critical industries.

Hot Products

202 Hot Rolled Stainless Steel Sheet

Wuxi Jianbanghaoda Steel Co.,ltd is a large-scale 202 Hot Rolled Stainless Steel Sheet manufacturer and supplier in China. We have been specialized in steel for domestic and overseas for many years. Our products have a good price advantage and high quality , our oversea customers cover most of the European and American markets,. We look forward to becoming your long-term partner in China.201 Cold Rolled Stainless Steel Tube

Wuxi Jianbanghaoda Steel Co.,Ltd. is a large-scale 201 Cold Rolled Stainless Steel Tube manufacturer and supplier in China. We have been specialized in steel for domestic and overseas for many years. Our products have a good price advantage and high quality, our oversea customers cover most of the European and American markets. We look forward to becoming your long-term partner in China.201 No.4 Stainless Steel Sheet

Wuxi Jianbanghaoda Steel Co.,ltd is a large-scale 201 No.4 Stainless Steel Sheet manufacturer and supplier in China. We have been specialized in steel for domestic and overseas for many years. Our products have a good price advantage and high quality , our oversea customers cover most of the European and American markets,. We look forward to becoming your long-term partner in China.Stainless Steel Chequered Pattern Sheet

Wuxi Jianbanghaoda Steel Co.,ltd is a large-scale Stainless Steel Chequered Pattern Sheet manufacturer and supplier in China. We have been specialized in steel for domestic and overseas for many years. Our products have a good price advantage and high quality, our oversea customers cover most of the European and American markets. We look forward to becoming your long-term partner in China.2205 Duplex Stainless Steel Round Bars

Wuxi Jianbang Haoda Steel Co.,Ltd. is a outstanding steel manufacturer with more than 15 years experience selling stainless steel sheet/pipe/coil/bar products( including 2205 Duplex Stainless Steel Round Bars) at home and abroad. We mainly supply stainless steel sheet, stainless steel tube, stainless steel coil/strip and stainless steel rod etc.,Our products are strictly produced in accordance with standard GB,ASTM,EN , JIS and etc.“Customers Satisfaction” is our consistent commitment, with professional technical and service team , we provide customers with timely, professional and point-to-point after-sales service.Electrolytic Tinplate steel Sheet

As a leading exporter of high-quality tinplate (electrolytic tin-coated steel), Wuxi Jianbanghaoda Steel Co.,Ltd. is specialized in producing high quality of Electrolytic Tinplate steel Sheet. Our products is compliant with ASTM/JIS standards and ISO 9001-certified.We utilize advanced production lines and rigorous quality control to guarantee precision and durability. We have earned partnerships across Europe, North America, and Southeast Asia with competitive pricing, reliable delivery, and customized specifications.