What are the production processes for stainless steel coils?

What are the production processes for stainless steel coils? How to store stainless steel coils correctly?

The production process of stainless steel coils

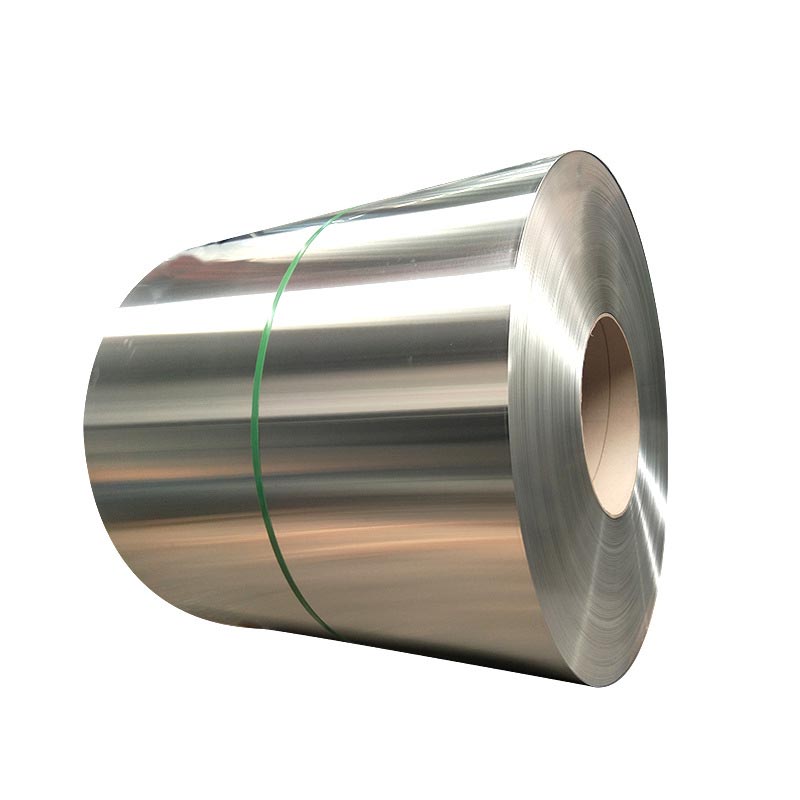

The production process of stainless steel coils mainly includes hot rolling, cold rolling, annealing, acid washing, and finishing. Firstly, stainless steel coils are heated to high temperatures through hot rolling process and then rolled into thicker coils. Subsequently, the cold rolling process further rolls the stainless steel coil to make its thickness thinner and surface smoother.

Annealing is a key step in the production of stainless steel coils, which eliminates internal stress and improves the ductility and toughness of the material through high-temperature treatment. Acid washing is used to remove the oxide layer on the surface of stainless steel coils, ensuring a clean surface. Finally, the finishing process flattens, cuts, and packages the stainless steel coil to meet customer requirements for size and surface quality.

Storage environment requirements for stainless steel coils

Proper storage of stainless steel coils is crucial for maintaining their performance. Stainless steel coils should be stored in a dry and ventilated indoor warehouse, avoiding contact with rainwater, humid air, or corrosive gases. If it must be stored outdoors, stainless steel coils should be tightly covered with waterproof cloth to prevent water vapor and pollutants from corroding the surface.

The stacking method of stainless steel coils also has strict requirements. Wooden or rubber gaskets should be used to separate each roll to avoid direct contact that may cause scratches or indentations. Meanwhile, stainless steel coils should be placed horizontally to prevent deformation caused by gravity.

Transportation and daily maintenance of stainless steel coils

When transporting stainless steel coils, specialized lifting equipment and protective devices should be used to avoid collision and friction damage to the surface. During the loading and unloading process, stainless steel coils should be handled with care to prevent edge collisions. Stainless steel coils stored for a long time should be regularly inspected to ensure that there is no rust or contamination.

If slight stains are found on the surface of the stainless steel coil, neutral cleaning agents can be used to wipe it, avoiding the use of chlorine containing or strong acid alkali cleaning agents to avoid damaging the corrosion resistance of the stainless steel coil.

Application and Market Trends of Stainless Steel Coils

Stainless steel coils are widely used in fields such as architectural decoration, automobile manufacturing, home appliance production, and chemical equipment. With the advancement of stainless steel coil processing technology, the demand for ultra-thin and high-strength stainless steel coils continues to grow. In the future, environmentally friendly stainless steel coils and special alloy stainless steel coils will become a new trend in the market.

Choosing the correct production process and storage method can effectively extend the service life of stainless steel coils and ensure their stable performance. Both manufacturers and end-users should pay attention to the storage management of stainless steel coils to maximize their performance.

- Why Does Tinplate Steel Win Real-World Packaging Projects Today?

- Surface Quality Inspection Methods and Precautions for 304 Stainless Steel Sheet

- What is the Manufacturing Process of Stainless Steel Tube?

- Welding Quality Measures for 304 Stainless Steel Seamless Tubes

- How to Choose the Stainless Steel Tube for Your Industrial Needs?

- Bright Annealing Conditions for 304 Stainless Steel Tube