Industry News

16 2025-06

16 2025-06 What is the corrosion resistance ofStainless Steel Tubes, and which industries most commonly use them?

Stainless steel pipes are widely favored for their exceptional corrosion resistance. These pipes contain at least 10.5% chromium, which forms a dense chromium oxide protective film on the surface, effectively resisting erosion from water, air, and various chemicals. Among them, 304 and 316 stainless steel pipes exhibit outstanding corrosion resistance, with 316 stainless steel pipes offering superior resistance to chloride corrosion due to the addition of molybdenum.

13 2025-06

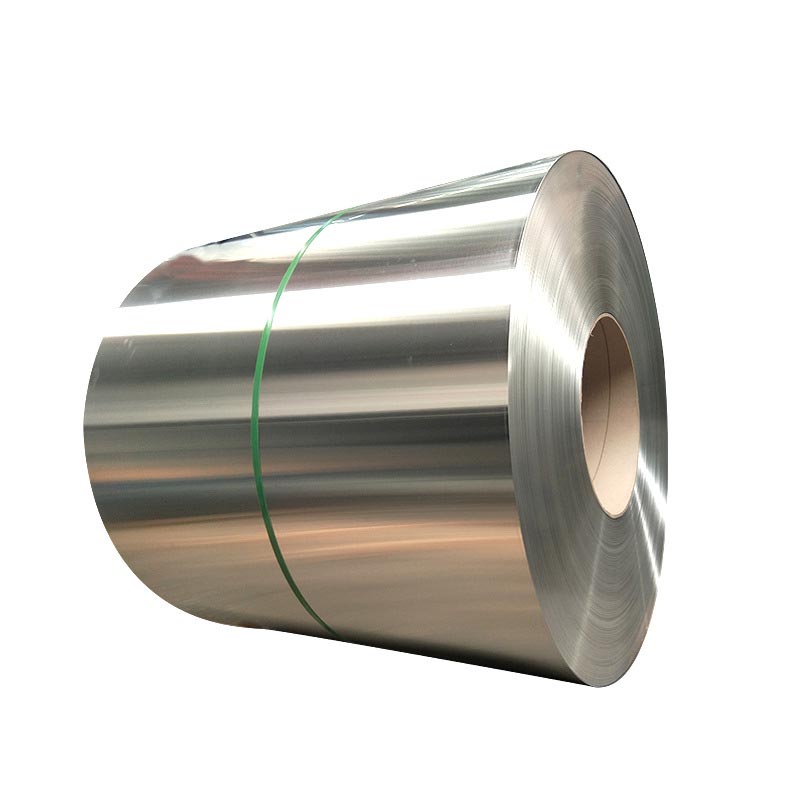

13 2025-06 What are the production processes for stainless steel coils?

The production process of stainless steel coils mainly includes hot rolling, cold rolling, annealing, acid washing, and finishing. Firstly, stainless steel coils are heated to high temperatures through hot rolling process and then rolled into thicker coils. Subsequently, the cold rolling process further rolls the stainless steel coil to make its thickness thinner and surface smoother.

10 2025-06

10 2025-06 What Are the Specifications of Stainless Steel Bars? How to Identify High-Quality Stainless Steel Bars?

The specifications of stainless steel bars mainly include four categories: diameter, length, material, and surface condition. Common diameters range from 1mm for small sizes to 300mm for large-diameter bars, with standard lengths typically being 3-6 meters in fixed or random sizes. Among various materials, 304 and 316 stainless steel bars are the most widely used, with 316 stainless steel bars offering better corrosion resistance due to their molybdenum content.

04 2025-06

04 2025-06 What are the applications of stainless steel profiles in the construction industry?

Stainless steel profiles have become an important material in modern architecture due to their excellent corrosion resistance and aesthetic properties. In the design of building facades, stainless steel profiles are often used as curtain wall support structures and decorative lines, and their unique metallic texture can enhance the overall grade of the building. 304 stainless steel profiles are particularly suitable for outdoor building applications due to their excellent weather resistance.

26 2025-05

26 2025-05 What is the difference between PR stainless steel and other stainless steels?

PR stainless steel is a special alloy stainless steel that has significant differences compared to traditional 304 and 316 stainless steel. The most prominent feature of PR stainless steel is its excellent corrosion resistance, especially in high chloride ion environments, which far exceeds conventional stainless steel. This characteristic makes PR stainless steel the preferred material for harsh environments such as chemical and marine engineering.

20 2025-05

20 2025-05 What special environments is PR stainless steel suitable for?

PR stainless steel performs excellently in strong acid and alkali environments in the chemical industry. Compared to ordinary stainless steel, PR stainless steel can withstand higher concentrations of corrosive media such as sulfuric acid and hydrochloric acid, making it particularly suitable for use in chemical equipment manufacturing. PR stainless steel can still maintain stable corrosion resistance in extreme environments with pH values below 2 or above 12.