How to Control the Processing Precision of Aluminum Coil? What Are the Application Prospects of Aluminum Coil in Packaging Industry?

How to Control the Processing Precision of Aluminum Coil? What Are the Application Prospects of Aluminum Coil in Packaging Industry?

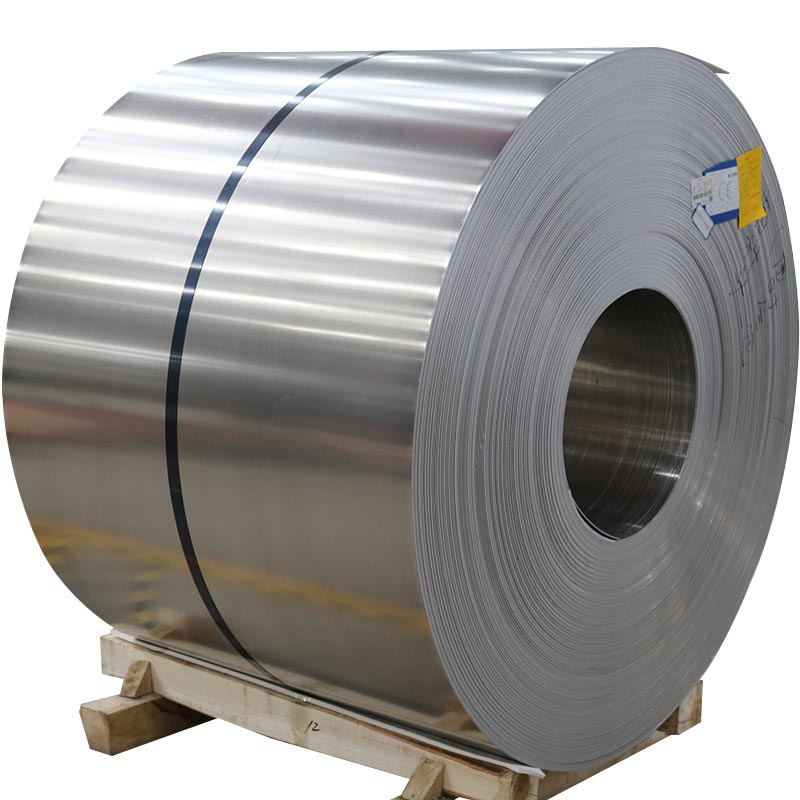

Aluminum Coil has become increasingly important in modern manufacturing due to its excellent formability and precision processing capabilities. The processing precision of Aluminum Coil is primarily controlled through advanced rolling technologies, precise tension control systems, and automated thickness monitoring devices. Modern production lines for Aluminum Coil can achieve thickness tolerances within ±0.01mm, ensuring consistent quality for various industrial applications. The surface finish of Aluminum Coil is another critical factor, which is maintained through specialized polishing and coating techniques.

In the packaging industry, Aluminum Coil demonstrates tremendous application potential. The food packaging sector particularly benefits from Aluminum Coil's barrier properties against moisture, light, and oxygen. Pharmaceutical packaging utilizes Aluminum Coil for blister packs and foil seals due to its sterile preservation qualities. Recent innovations in Aluminum Coil processing have enabled thinner gauges without compromising strength, significantly reducing material costs for packaging manufacturers. The recyclability of Aluminum Coil also aligns with the growing demand for sustainable packaging solutions.

Quality control measures for Aluminum Coil involve multiple inspection stages. Automated optical scanners examine Aluminum Coil for surface defects, while X-ray thickness gauges ensure dimensional accuracy. The alloy composition of Aluminum Coil is carefully monitored to maintain optimal mechanical properties for specific applications. These stringent controls enable Aluminum Coil to meet the high standards required in precision industries like electronics and automotive manufacturing.

The future of Aluminum Coil in packaging looks particularly promising with emerging technologies. Smart packaging solutions incorporating Aluminum Coil can now include RFID tags and freshness indicators. The development of nano-coated Aluminum Coil offers enhanced antibacterial properties for medical packaging. As e-commerce continues to grow, Aluminum Coil-based protective packaging is becoming increasingly popular for its durability and lightweight characteristics.

With continuous advancements in processing technology and expanding applications, Aluminum Coil is poised to play an even greater role across industries. The packaging sector especially stands to benefit from Aluminum Coil's unique combination of properties, driving innovation in product protection and sustainability. As manufacturers develop more sophisticated Aluminum Coil products, we can expect to see broader adoption in both traditional and emerging markets.

- Why Does Tinplate Steel Win Real-World Packaging Projects Today?

- Surface Quality Inspection Methods and Precautions for 304 Stainless Steel Sheet

- What is the Manufacturing Process of Stainless Steel Tube?

- Welding Quality Measures for 304 Stainless Steel Seamless Tubes

- How to Choose the Stainless Steel Tube for Your Industrial Needs?

- Bright Annealing Conditions for 304 Stainless Steel Tube