Offering superior corrosion resistance and excellent formability, our 202 NO.1 2B BA Cold Rolled Stainless Steel Strip is ideal for a wide range of industrial applications. This high-quality material is crafted to meet stringent standards, ensuring durability and performance in environments where reliability is critical. Whether used in construction, automotive components, or kitchen equipment manufacturing, it provides consistent results. Manufacturers and engineers prefer it for its cost-effectiveness and versatility, making it a top choice for projects requiring precision and longevity. Explore the detailed specifications below to understand why it stands out in the market.

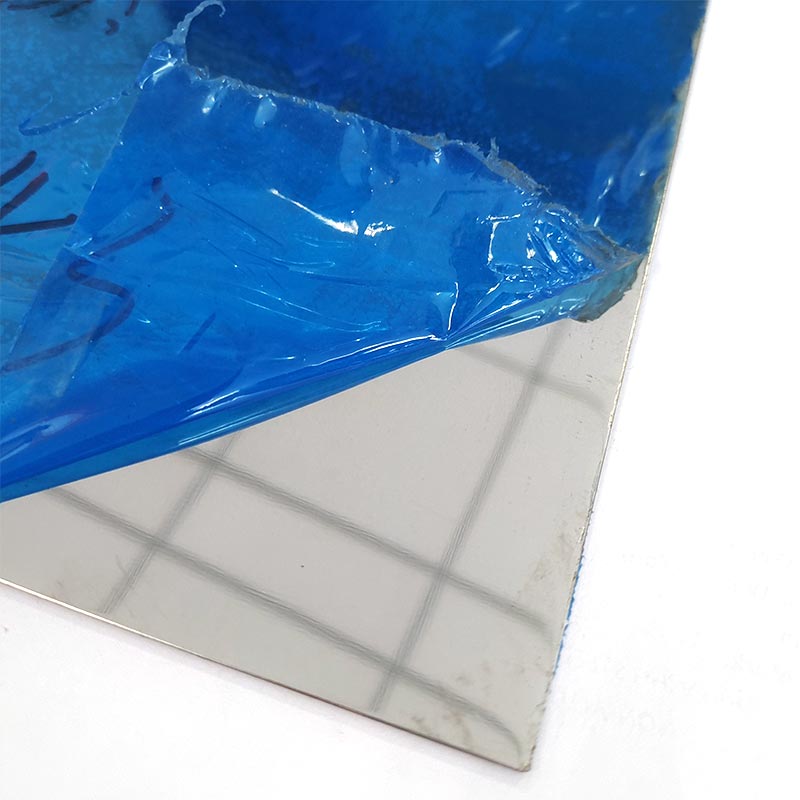

Our 202 NO.1 2B BA Cold Rolled Stainless Steel Strip undergoes a meticulous cold rolling process that enhances its surface finish and mechanical properties. The "2B" designation refers to a smooth, moderately reflective surface achieved through cold rolling, annealing, and pickling, while "BA" indicates a bright annealed finish for superior aesthetics. This strip is produced from grade 202 stainless steel, which contains a balanced composition of chromium, nickel, and manganese, contributing to its resistance to oxidation and corrosion. It is available in various thicknesses, widths, and lengths to accommodate diverse fabrication needs, ensuring easy integration into your production lines without compromising on quality or performance.

Product Specifications

- Material Grade: 202 Stainless Steel

- Standard: ASTM A240, AISI 202

- Surface Finish: 2B (Cold Rolled, Annealed, and Pickled) and BA (Bright Annealed)

- Thickness Range: 0.1mm to 3.0mm

- Width Range: 10mm to 1000mm

- Length: Custom coils or cut-to-length strips available

- Hardness: Rockwell B (RB) 85 max for annealed condition

- Tensile Strength: 515 MPa min

- Yield Strength: 205 MPa min

- Elongation: 40% min in 2 inches

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 17.00 - 19.00 |

| Nickel (Ni) | 4.00 - 6.00 |

| Manganese (Mn) | 7.50 - 10.00 |

| Silicon (Si) | 1.00 max |

| Carbon (C) | 0.15 max |

| Phosphorus (P) | 0.06 max |

| Sulfur (S) | 0.03 max |

| Nitrogen (N) | 0.25 max |

Hot Products

6063 T6 Aluminum Round Bar

Wuxi Jianbanghaoda Steel Co.,Ltd. is a specialized metal material manufacturer in China, which is the manufacturer and supplier of 6063 T6 Aluminum Round Bar. We have been in metal domestic and international business for over 15 years. We have our own warehouses located in many cities.Our steel products have competitive price and good quality .Our oversea customers cover all over the world oversea markets. We look forward to establishing long-term business relationship with all customers.430 BA Stainless Steel Sheet

Wuxi Jianbanghaoda Steel Co.,ltd is a large-scale 430 BA Stainless Steel Sheet manufacturer and supplier in China. We have been specialized in steel for domestic and overseas for many years. Our products have a good price advantage and high quality, our oversea customers cover most of the European and American markets. We look forward to becoming your long-term partner in China.6082 T6 Aluminum Round Bar

Wuxi Jianbanghaoda Steel Co.,Ltd. is a specialized metal material manufacturer in China, which is the manufacturer and supplier of 6082 T6 Aluminum Round Bar. We have been in metal domestic and international business for over 15 years. We have our own warehouses located in many cities.Our steel products have competitive price and good quality .Our oversea customers cover all over the world oversea markets. We look forward to establishing long-term business relationship with all customers.420 Cold Rolled Stainless Steel Coil

Wuxi Jianbang Haoda Steel Co., Ltd. is an emerging company selling stainless steel coil products( including 420 Cold Rolled Stainless Steel Coil and some other ss material) at home and abroad.

We mainly supply stainless steel plate, stainless steel pipe, stainless steel coil and stainless steel bar etc.,Our products are strictly produced in accordance with national standard GB,ASTM,EN, JIS and etc.“Customers Satisfaction” is our consistent commitment, with professional technical and service team , we provide customers with timely, professional and point-to-point after-sales service.S235jr Q235B Carbon Steel Sheet

Wuxi Jianbanghaoda Steel Co.,ltd is a professional steel exporter in China , which is one of the biggest steel manufacturer and supplier, we offer carbon steel plate (such as S235jr Q235B Carbon Steel Sheet ),carbon steel pipe , carbon steel coil and carbon steel bar.We have been in steel domestic and foreign trade for over 15 years. We also have our own warehouses located in many cities.We Offer customized cutting, logistics support, and timely delivery, we serve global clients as a trusted steel solutions partner. Our oversea customers cover all over the world oversea markets. We look forward to establishing long-term business relationship with all customers.430 2B Stainless Steel Sheet

Wuxi Jianbanghaoda Steel Co.,ltd is a large-scale 430 2B Stainless Steel Sheet manufacturer and supplier in China. We have been specialized in steel for domestic and overseas for many years. Our products have a good price advantage and high quality , our oversea customers cover most of the European and American markets,. We look forward to becoming your long-term partner in China.